BTRboard revolutionizes construction by delivering superior thermal resistance performance that saves energy, improves home health, and reduces environmental impact. With BTRboard, builders can meet Tier Code requirements while reducing materials and labour.

BTRboard enables builders to achieve code-compliant effective R-values using 2×4 construction, or exceed it with standard 2×6 construction. A BTRboard wall with 2x4s at 16″ o.c. and R-12 batts delivers an effective R Value of 17.4; meaning less lumber, less insulation, and a simpler assembly.

A 2x4 BTRboard wall provides UP TO 10% BETTER insulation than a standard 2x6, saving cost and maximizing floor space!

A 2x6 BTRboard wall performs UP TO 40% BETTER than a standard 2x6, using the same amount of lumber.

| Wall Type | Wall Effective-R | Added Cost/sqft | Cost Per Effective-R | Summary |

|---|---|---|---|---|

| BTRboard | R-28 | $2.97 | $0.51 | The Most Cost Effective Way To Add R |

| Double Wall(2x4 + R19) | R-27.7 | $6.69 | $0.55 | Costly Labour Requires More Space |

| Add 1.5" EPS | R-26 | $3.25 | $0.56 | Requires picture framing; harder WRB/cladding |

| Add 1.5" XPS | R-27.5 | $5.20 | $0.63 | Requires picture framing; less vapor-permeable |

| Fibreglass upgrade | R-25 | $1.40 | $0.91 | Low gain for high cost. Not effective |

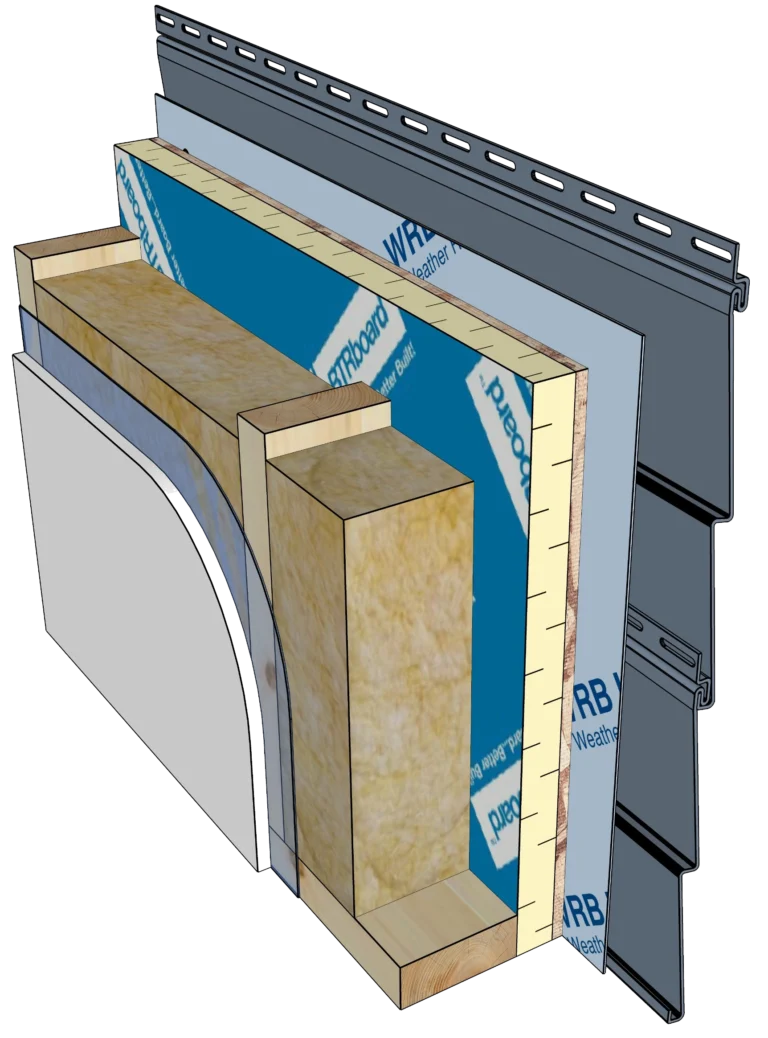

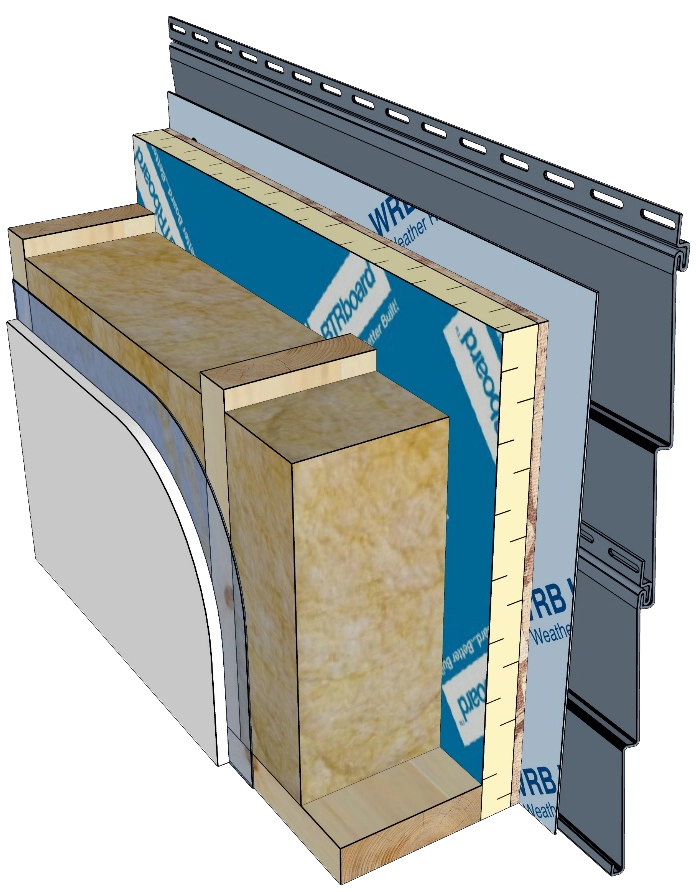

BTRboard offers a faster, more efficient install when compared to EPS Foam Board by eliminating extra steps like strapping, furring, and picture framing around windows. Cladding and windows can be fastened directly to the panel, just like standard construction, reducing labour, simplifying detailing, and cutting material costs, all while delivering superior performance.

BTRboard offers a faster, more efficient install when compared to EPS Foam Board by eliminating extra steps like strapping, furring, and picture framing around windows. Cladding and windows can be fastened directly to the panel, just like standard construction, reducing labour, simplifying detailing, and cutting material costs, all while delivering superior performance.

BTRboard unique combination of substrates fused with polyurethane foam and fibreglass add additional structural stability to walls, making it ideal for panelization and modular build applications. Nail joint testing conducted at University of Alberta Structural Labs verifies that BTRboard out performs standard OSB wall systems.

Walls built with BTRboard OSB are 21% stronger than standard OSB installations.

No Data Found

Walls built with BTRboard FireX installed with the recommended 3 1/2″ ring nails are 96% stronger.

No Data Found

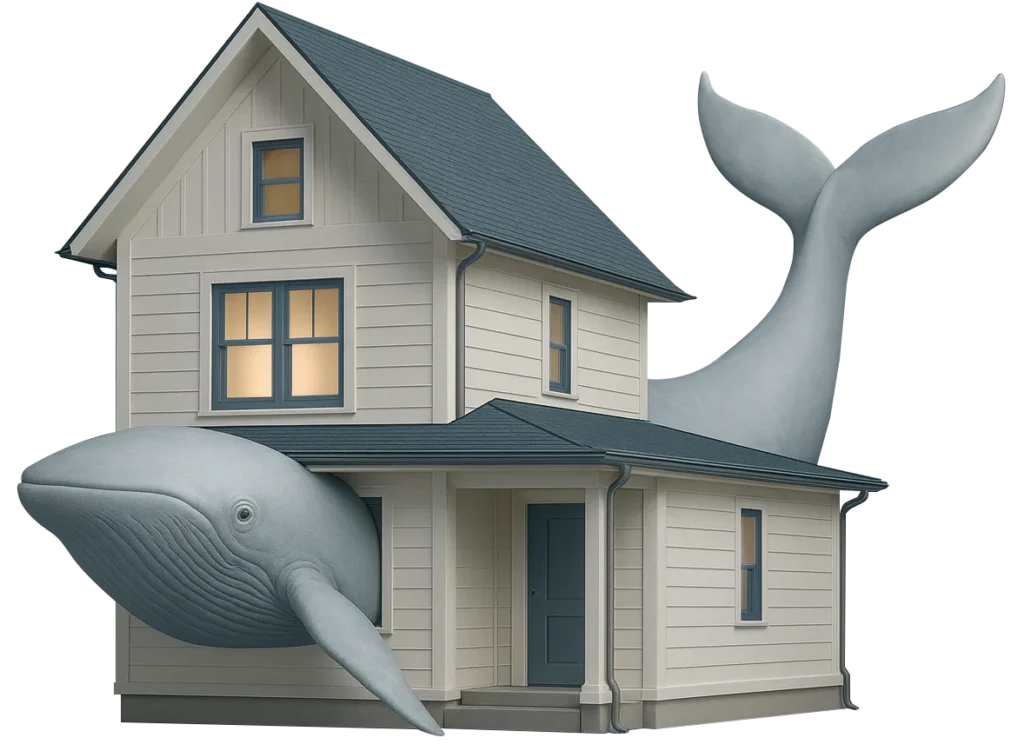

Up to 23% of the composition of an exterior wall assemblies is studs, which are thermal conductors. For A 2000 sqft. detached home that ads up to 500 sqft. of exterior wall is uninsulated! That’s bigger than the size of an adult humpback whale.

BTRboard is a complete exterior insulation system that stops thermal-loss through studs and air gaps in wall assemblies.

No Data Found

BTRboard enhances home comfort by integrating sheathing with a layer of medium-density polyurethane foam, resulting in better thermal resistance.

This innovation significantly minimizes noise penetration from outside the home leading to a quieter environment.

BTRboard increases a wall systems R-value up to 8.75, dramatically reducing heating and cooling costs by up to 20%. This translates to significant annual savings on energy bills for homeowners.

BTRboard helps prevent water penetration and condensation reducing the risk of mould growth inside walls. Its fiberglass facer is moisture-resistant unlike traditional OSB, which can support mould growth at just 13% moisture content.